By Robert Segers

Often overlooked and many times an afterthought, the proper matting at your building’s entrances can be the best investment you make to protect your interior flooring as well as the safety and well-being of your students, faculty, staff and visitors.

Eighty percent of soil, dust, contaminants and moisture are tracked in on the shoes of building staff, students and visitors.

According to the International Sanitary Supply Association (ISSA), finding and removing a pound of dirt from a building costs approximately $600. One square yard of carpet accumulates one pound of dirt in a week; twice that in inclement weather.

In addition to the maintenance costs associated with tracking the elements inside your building, the life expectancy of the interior surfaces will be reduced dramatically.

Fifteen feet of effective, high-performance matting traps and holds up to 75 percent of soil at the door; 30 feet can remove as much as 100 percent (ISSA).

Effective matting also reduces slip and fall exposure. Slips and falls are not only dangerous to students, staff and visitors, they are expensive. A single incident could run up to $50,000 (including medical costs, lost work time and worker’s compensation).

The most effective entrance matting products will do three things: stop, store and provide a safe walking surface.

Entrance matting will remove soil and moisture from the shoe and keep it from getting further into your building. The most effective matting will provide a combination of scraping, wiping and storing of debris and slush to stop the spread of soil and contaminants.

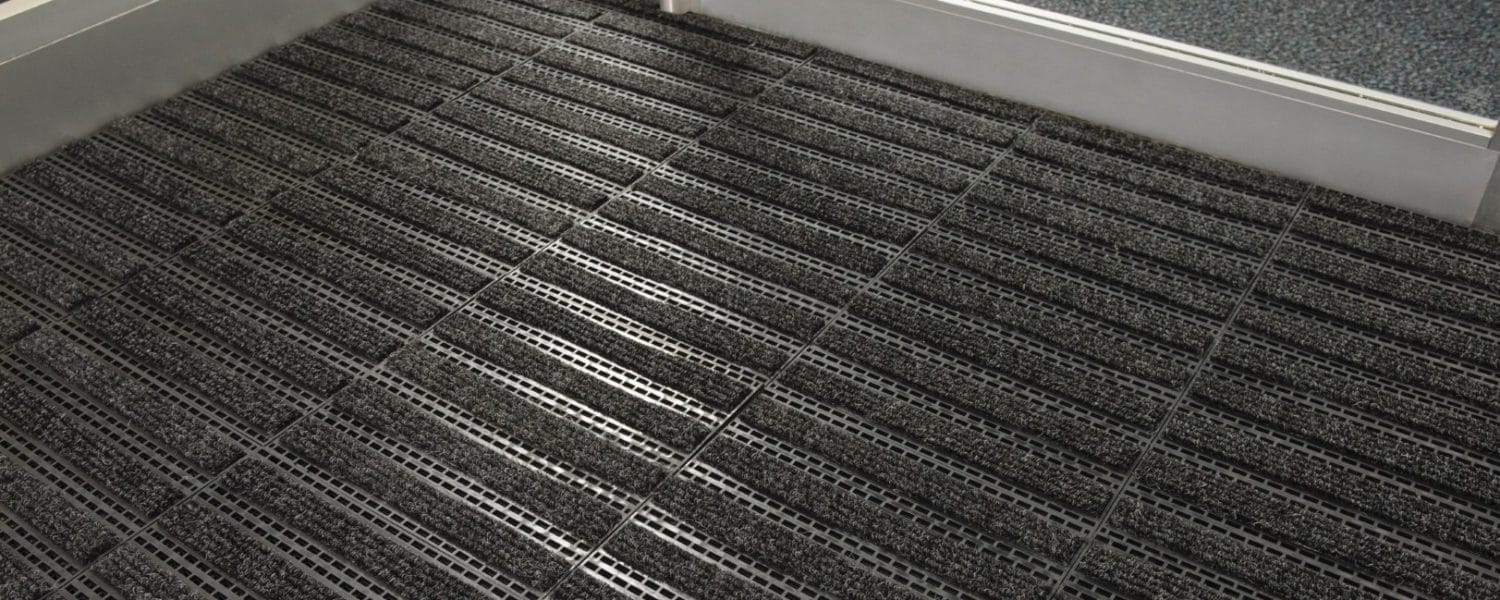

An effecting entrance mat will store the soil and water for removal. This can be accomplished in a number of ways. Matting with a bi-level construction will allow an upper walking surface that traps moisture and dirt in a lower reservoir that is later removed.

Other matting products will have holes or perforations that allow moisture to pass through the mat either to a drain in the vestibule or under the mat until it is evaporated or later removed.

A key feature to the proper entrance matting is a walking surface that remains slip-resistant in all types of weather conditions.

Entrance matting is available in a number of styles and materials to meet the unique features of your building, grounds and climate. Mats can be made of metal, rubber, vinyl, carpet, recycled products or combinations of these materials.

They can be installed as interlocking tiles, glue-down tiles and matting or as a loose-laid product. The type of matting chosen largely depends on budget, expected foot traffic, climate conditions and the types of surfaces leading into your building.

The proper entrance matting will also reduce or eliminate the need for additional rugs or carpet walk-off mats, which are often eyesores and potential tripping hazards.

The ideal location for the entrance mats would be in the vestibule area of your building. These are usually recessed in the foyer, often between sets of double doors.

If there is not a vestibule at your entrance, a mat directly on the surface, with beveled edging on all sides, would be recommended.

Because children (and many adults) do not take the time to wipe their feet when entering a building, the longer the run of entrance matting you have the more effective it will be in removing dirt and moisture.

Once the proper entrance matting is selected and installed, it is important to follow the recommended maintenance procedures in order to get the optimal performance and longevity from your matting.

Most products require daily vacuuming and soil removal, with regular water and detergent cleaning and periodic extraction cleanings.

In summary, entrance matting is a vital part of a building’s soil management and asset protection program.

Matting with bi-level construction that both scrapes and stores soil and moisture helps keep dirt and moisture from tracking further into the building and causing added expense, potential trip and fall hazards, and damage of interior floor surfaces.

Proper installation and maintenance will protect your investment and add to the aesthetic appeal of your facility.

Robert Segers is the president of The R. C. Musson Rubber Company, a manufacturer and distributor of stair treads and matting products located in Akron, Ohio, www.mussonrubber.com.